- TIGRES GmbH

- Products

- TIGRES® Lab

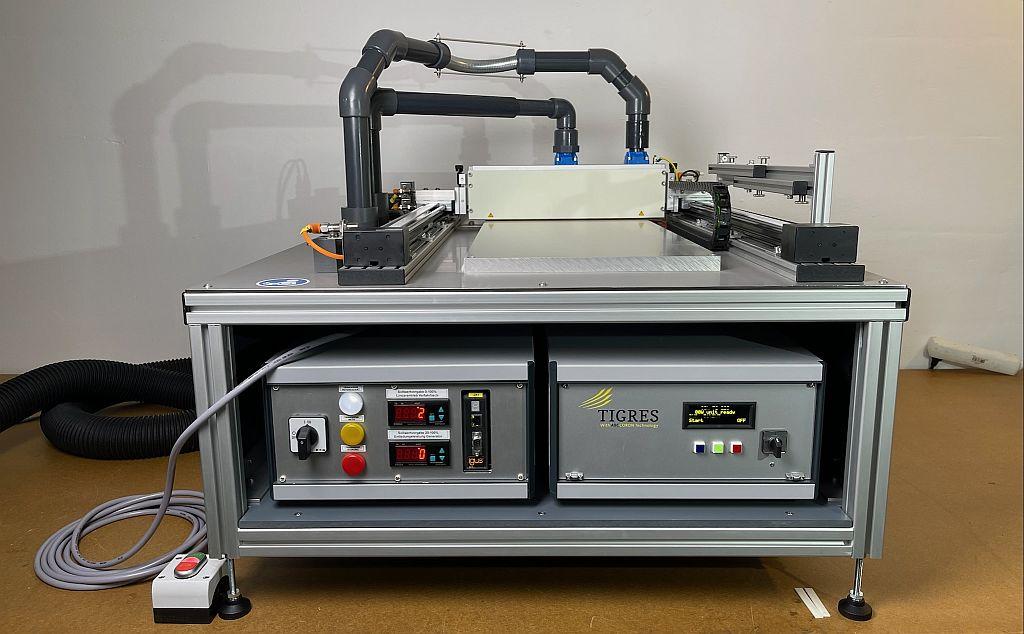

- DBD Corona laboratory unit A3 LAB

Corona laboratory device

TIGRES® DBD A3 LAB

Die Coronavorbehandlung, physikalisch handelt es sich um eine dielektrisch behinderte Entladung (DBE, im englischen DBD), wird seit Jahrzehnten insbesondere für die Vorbehandlung von Folien eingesetzt und ist eine der am meisten eingesetzten Plasmavorbehandlungarten in der Industrie.

Das Gerät wurde insbesondere für den Einsatz vor allem in Laboren, Universitäten und Hochschulen, Einrichtungen zur Forschung und Gesundheit sowie zum Einsatz im Technikum zur industriellen Prozessentwicklung entwickelt.

- Reproduzierbarkeit der Vorbehandlungsparameter für Forschung oder Serienproduktion

- Flexible Einstellung von Corona-Leistung und Vorschubgeschwindigkeit während der Entladung (über Bedieneinheit auf Vorderseite)

- Einfache Einstellung des zu behandelnden Arbeitsbereiches (mechanisch)

| Arbeitsbereich | A3, 300 x 420mm |

| Zu behandelnder Bereich | Mechanisch einstellbar |

| Coronaleistung | Max. 600 W, einstellbar von 20-100% |

| Anzahl Elektroden | 2 |

| Vorschubgeschwindigkeit | Bis zu 0,5 m/sek (30 m/min), einstellbar 0-100% |

| Behandlungshöhe | max. 3 mm, einstellbar |

| Behandelbare Materialien | Kunststoffe, Gewebe, Textilien, Metall, Glas |

Absaugung integriert, Ozonfilter optional erhältlich

Simple operation

The feed rate and the corona power are set directly via the digital setting range. The treatment is triggered by an external control module, so that the place of operation is flexible.

Simple integration

The device is simply connected to a suitable compressed air supply and 230 V and is immediately ready for operation.

adjustable power

The continuously adjustable coronal power allows precise work for accurate results. The corona dose can thus be adjusted for a wide variety of applications and materials.

Do you need advice?

Our Sales & Technical guidance team

Do you have any questions about the DBD-A3 Lab, require further information, or need advice? Our employees and their specialist knowledge are at your disposal.