Securely bonding and sealing batteries

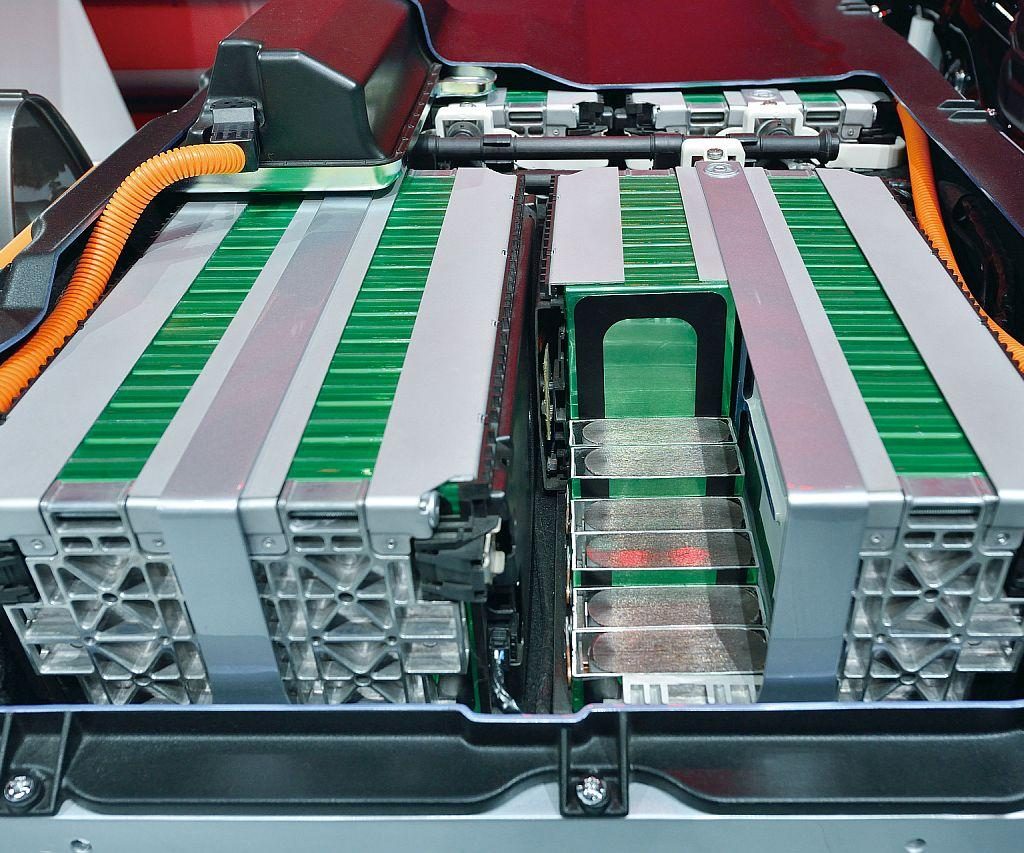

High-performance battery systems for electromobility consist of battery cells that are assembled in stacks and installed in battery housings.

Plasma pretreatment systems are used to permanently bond the materials used for this purpose securely for a long service life under all weather and driving conditions, to ensure the safe dissipation of the process heat generated by the batteries to the outside, and to seal the battery housings securely.

Easy Integration & High Scalability

TIGRES plasma nozzle systems can be easily integrated into fully automated inline battery cell production processes, making them ideal for high production speeds and volumes.

CAT technology

Our most powerful plasma nozzle with patented discharge technology

T-SPOT technology

The universal plasma standard solution with a wide performance spectrum

MEF technology

Proven multi-nozzle system for large treatment widths

T-JET technology

Corona pretreatment for heat-sensitive surfaces

Advantages of plasma pretreatment for battery systems

- Simple and clean process through cost-efficient, environmentally friendly electrical plasma treatment

- Reliable reproducibility of pretreatment, even for sensitive surfaces, due to power-adjustable and controlled plasma discharge

- Full monitoring of all process-relevant parameters through real-time monitoring with TIGRES SQI (System Quality Index)