Automotive & E-mobility

In the automotive industry, consistent high quality processing is a requirement for efficient and cost-effective production.

The extensive and steadily growing use of adhesives, especially in the case of plastic connections, requires a consistently high level of surface adhesion so that a secure and long-term stable adhesive connection can be created.

Mainfeatures

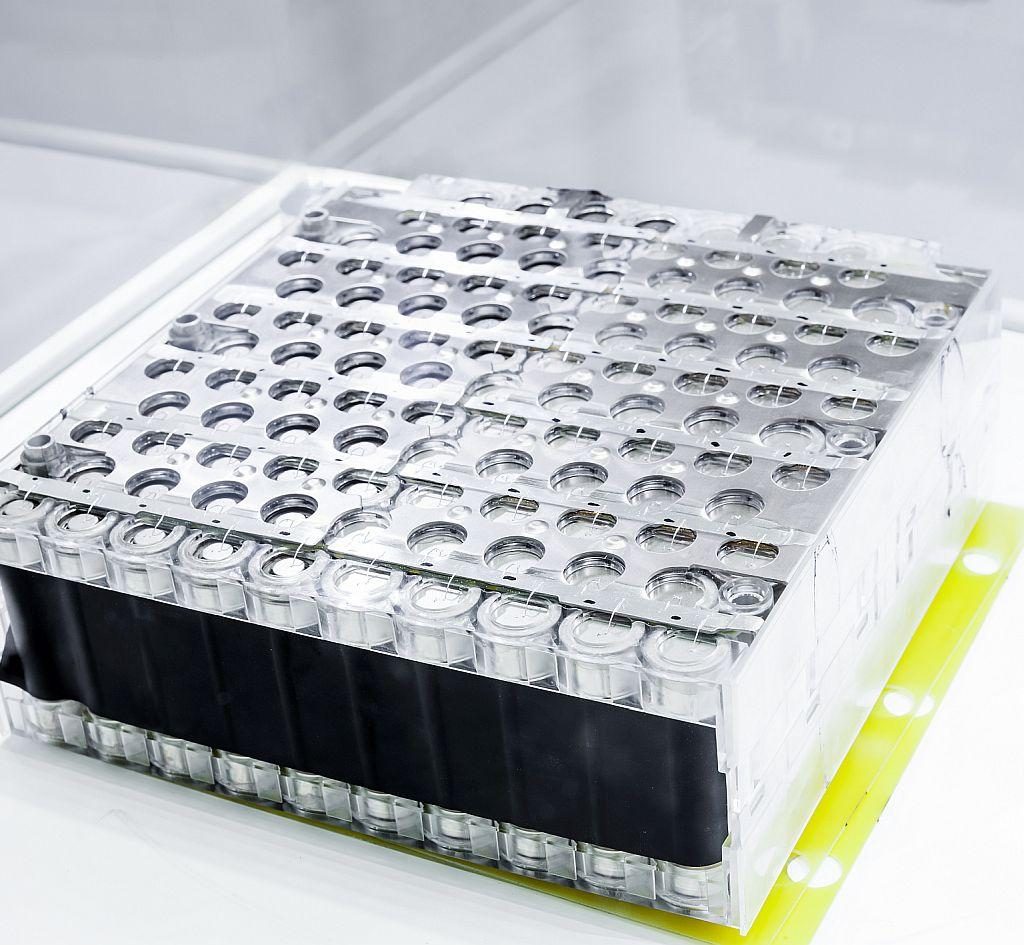

Plasma pretreatment at atmospheric pressure is a simple, inexpensive and, in particular, controllable type of pretreatment. The so-called activation enables optimal adhesive forces and wettability.

Integration & Automation

The plasma nozzles can easily be integrated into existing production lines or robot handling systems.

- works residue-free on the surface

Safe reproducibility

Reproducible, homogeneous pretreatment, even with sensitive surfaces, through adjustable and regulated plasma discharge.

- self-adjusting treatment parameters

Real-time monitoring

All process-relevant parameters are monitored by real-time monitoring with TIGRES SQI(System Quality Index) and are available for evaluation.

- fully Industry 4.0 capable

Related topics

The surface properties of polyolefins such as PP, PE with their inherently very low surface energies are the reason that subsequent adhesive processes such as gluing, painting and printing are a challenge.

Plastics such as PVC, PU, PC and others, as well as metals and glass, often need their adhesive properties to be optimized and homogenized before further processing.

Classic pretreatment processes, such as priming or flame treatment, are often associated with complex implementation and handling, high running costs for consumption and storage, high health and environmental requirements and difficult process control.

Do you need advice?

Our Sales & Technical guidance team

Do you have any questions, would you like advice or more detailed information? Our employees and their specialist knowledge are at your disposal.