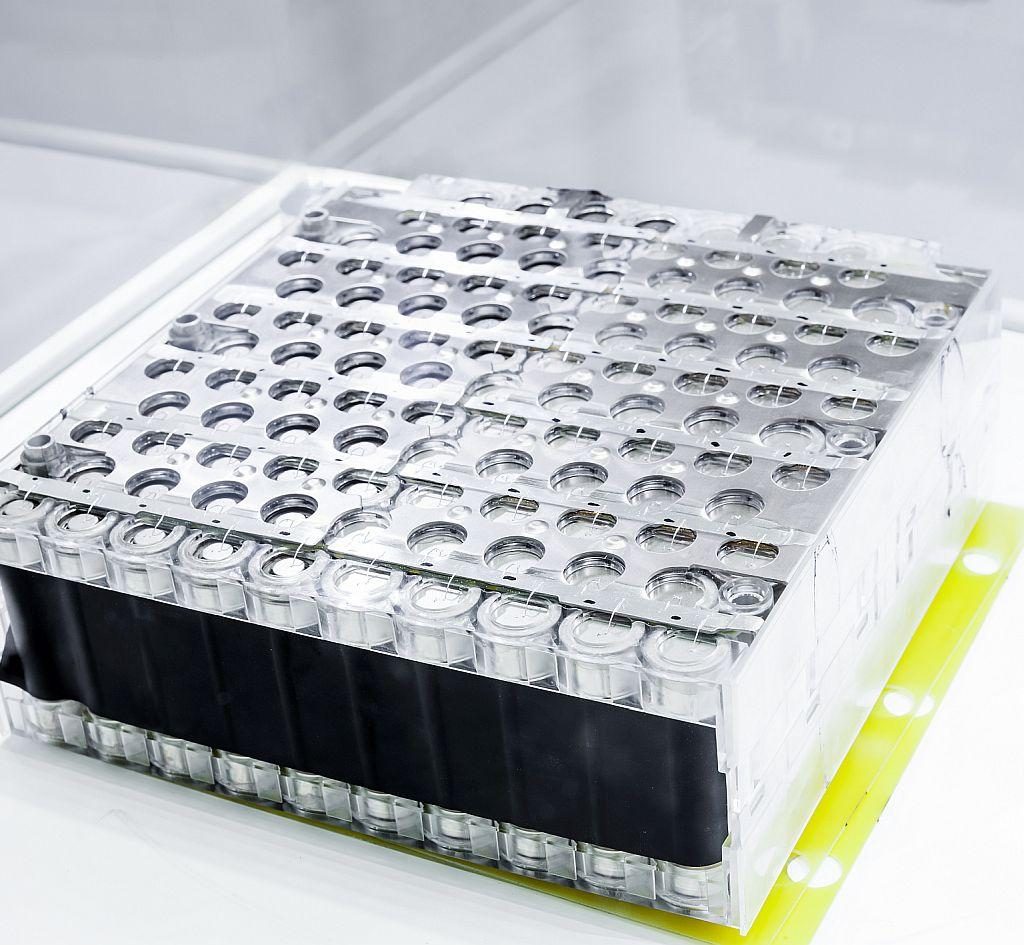

Safe cleaning of battery contacts and fuel cells

To achieve optimum results in coating processes and wire bonding of battery contacts, reliable and reproducible results are essential. Plasma pretreatment is used to prepare and clean the surface before bonding. Depending on the material to be treated and the process, air or forming gas is used as the process gas in the plasma nozzle.

Easy Integration & High Scalability

Forming gas consists of at least 95% nitrogen and up to 5% hydrogen. The low hydrogen content is in a non-critical mixing ratio. The forming gas causes a reduction of the material and can, for example, reduce oxidized copper or silver back to bare metal in a very short time.

TIGRES plasma nozzle systems can be easily integrated into fully automated inline production processes, making them ideal for high production speeds and quantities.

Advantages of plasma pretreatment for cleaning and reduction

- Simple and clean process through cost-efficient, environmentally friendly electrical plasma treatment

- Reliable reproducibility of pretreatment, even for sensitive surfaces, due to power-adjustable and controlled plasma discharge

- Full monitoring of all process-relevant parameters through real-time monitoring with TIGRES SQI (System Quality Index)