MEF technology

The potential-free atmospheric pressure plasma of this series enables scalable, homogeneous surface activation prior to bonding, printing, painting and coating of plastics, metals, paper, glass, cardboard, composites and textiles.

- TIGRES GmbH

- Products

- Plasma Systems

- MEF technology

Overview

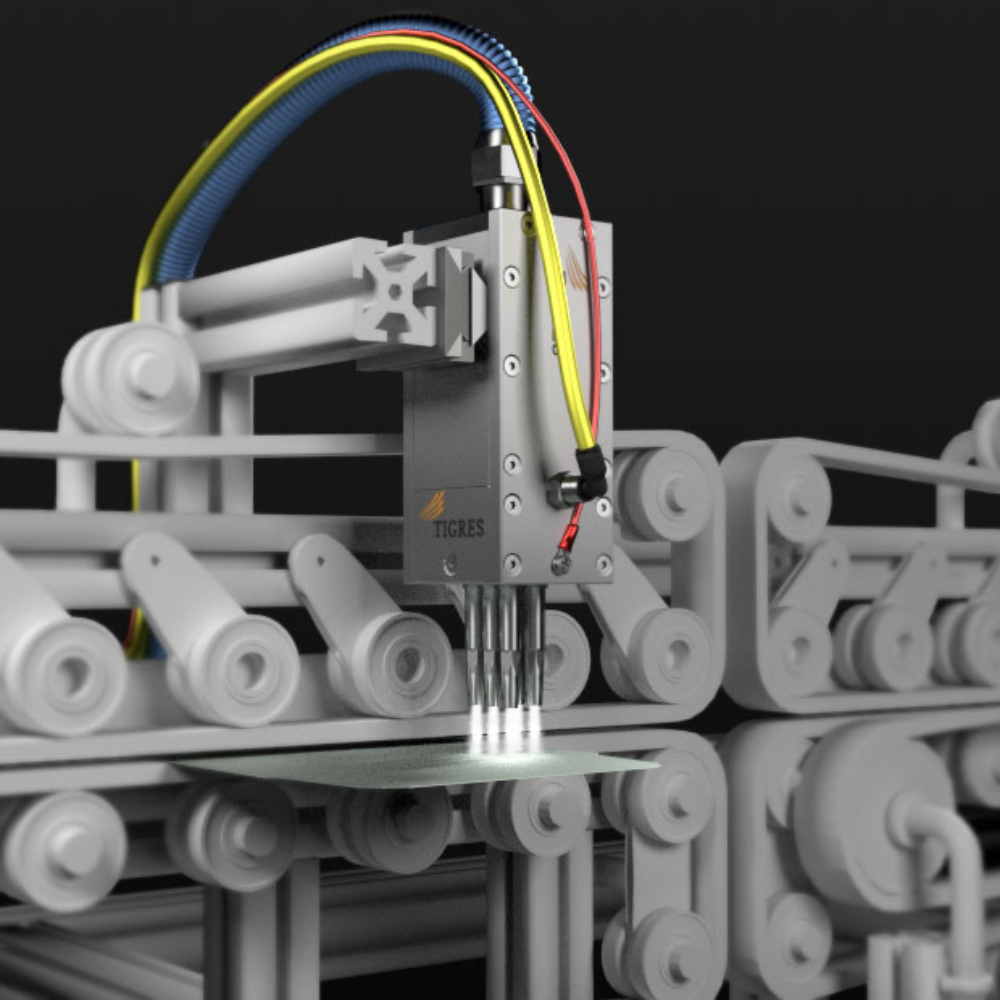

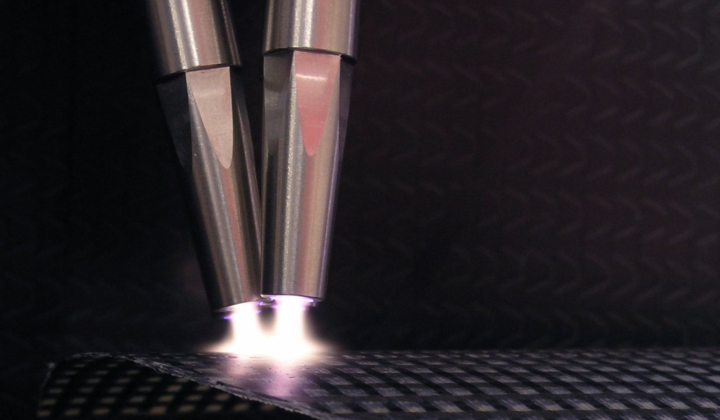

With MEF technology, the plasma is generated by an electric barrier discharge and the beam is directed onto the surface with the aid of compressed air.

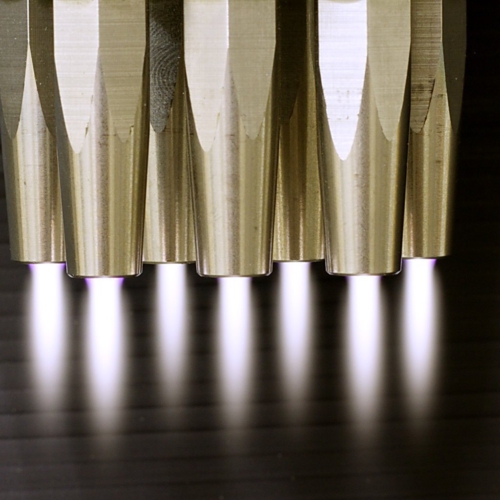

Whether a single nozzle for high-precision pretreatment, multiple nozzles for wider applications or plasma modules for extensive substrates - any application that our customer might have is possible with this technology.

Various process gases can be used to create special functional groups on the polymer surface.

Scalability

The supply lines to the MEF modules can run parallel or perpendicular to the nozzle.

Process integration

The supply lines to the MEF modules can run parallel or perpendicular to the nozzle.

Technical data

|

Output

|

200 W per nozzle

|

|

Number of tools

|

max. of 2 per Generator

|

|

Process gas

|

Air (others on request)

|

|

Transformator

|

external

|

|

EDC Technology

|

integrated

|

|

NDC2 Technology

|

integrable

|

Do you need advice?

Our Sales & Technical guidance team

Do you have questions about MEF technology, need further information or advice? Our employees and their specialist knowledge are at your disposal.