T-SPOT technology

The plasma T-SPOT series, with powerful plasma and a compact, lightweight plasma head design.

- TIGRES GmbH

- Products

- Plasma Systems

- T-SPOT technology

Overview

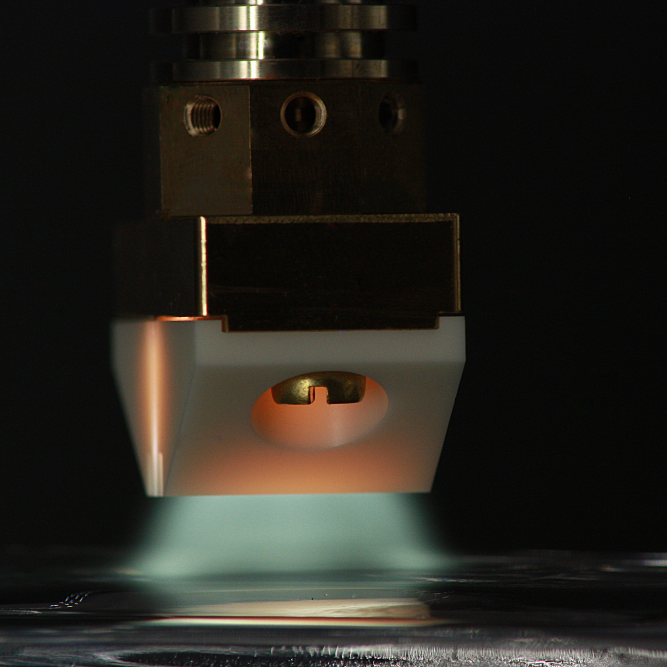

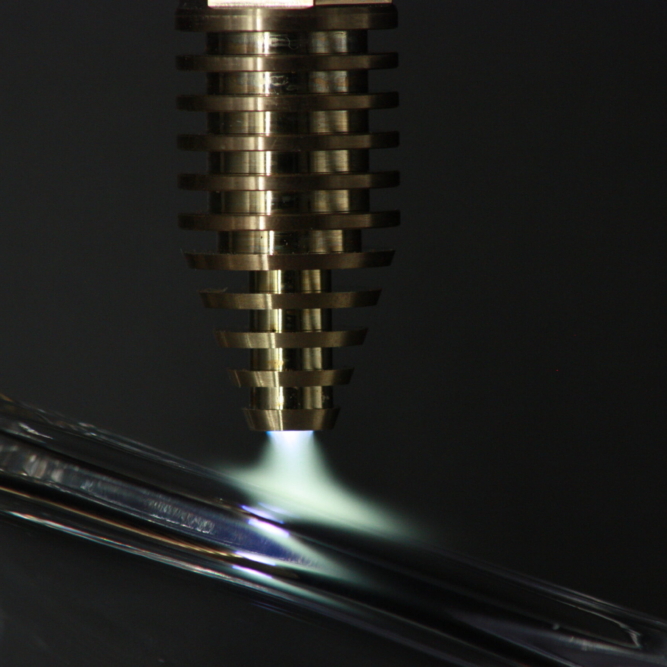

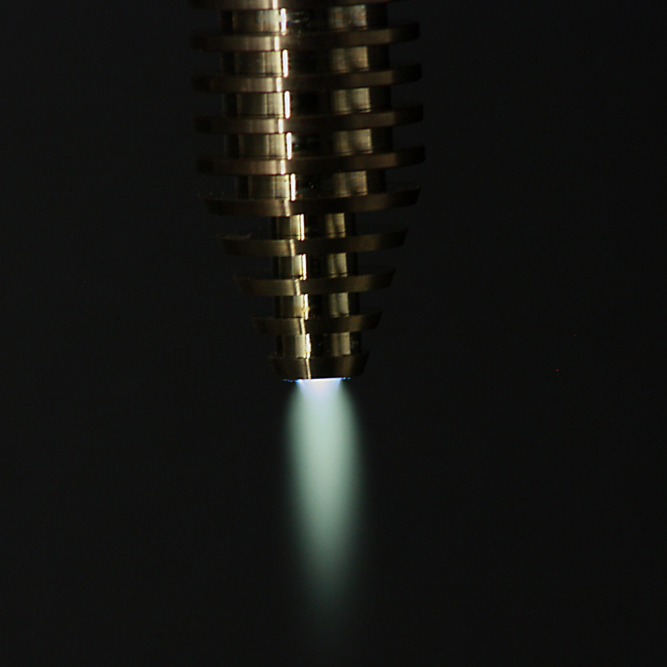

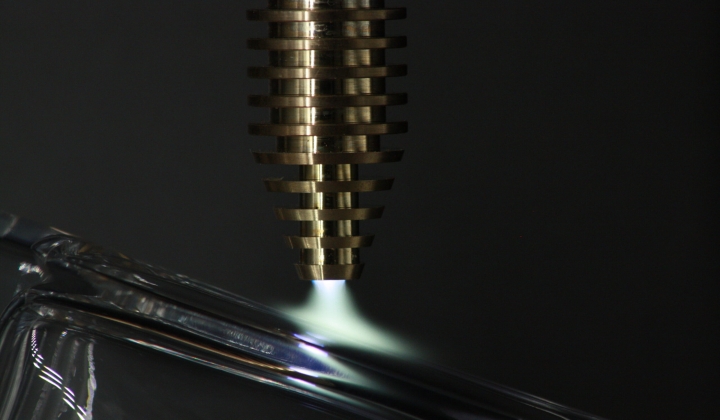

The discharge is sparked between the centered electrode and the nozzle serving as the counter electrode with the classically designed T-SPOT.

Due to the combination of the nozzle geometry and the electrical current forming in the nozzle, plasma is discharged in two places: The primary plasma with current filaments, which protrude until the nozzle opens, and the secondary plasma without current filaments (visible on the photos above).

The Plasma T-SPOT is a long-lasting standard solution that requires only minimal service.

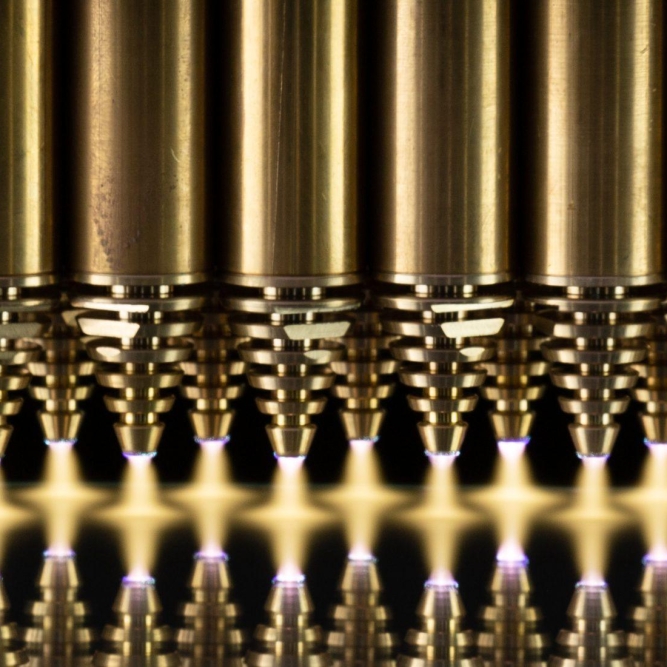

Scalability

Up to 4 heads per generator (networking of several generators possible). Plasma heads individually controllable, power adjustment also during discharge

Process integration

The proven classic: The advantages of the T-SPOT series plasma range lie in a flexibly adjustable, controlled plasma, its compact and lightweight head shape and robust design. Ideal for groove and surface treatment. Activation of plastics at low and high speeds, for effective plasma cleaning/fine degreasing of metal parts and for deburring plastic parts.

Technical data

|

Performance

|

250 - 500 W (T-Spot S3 500), 550 - 750 W (T-Spot S3 750), adjustable

|

|

Generator

|

|

|

Channels

|

1-4 nozzles per generator,

Networking of several generators possible |

|

Process gas

|

Air (others on request)

|

|

Potential-free

|

nahezu

|

|

Transformer

|

external

|

|

Plasma treatment width

|

Up to over 20 mm per nozzle, unlimited cascading as a multi-nozzle system for wide applications

|

|

Mechanical wear parts

|

no

|

Do you need advice?

Our Sales & Technical guidance team

Do you have questions about the T-SPOT technology, need further information or advice? Our employees and their specialist knowledge are at your disposal.